- Ceramics

- Artist Pages

- Asian Ceramics & Tea

- Ceramics Artist Links

- Ceramics Links

- Ceramics Terms Glossary

- Agateware

- Banding Wheel

- Bat, Throwing Bat

- Bisqueware, Biscuit Ware

- Blistering

- Blow Up

- Boat Anchor

- Calipers

- Carbon Coring, Black Coring

- Carbon Trap

- Chuck, Chum

- Coil

- Colorants

- Crazing

- Downdraft Kiln

- EPK, Edgar Plastic Kaolin

- Electric Kiln

- Extrusion, Extruder

- Fettle, Fettling Knife

- Force Dry

- Greenware

- Kaolinite

- Kilnsitter

- Overglaze

- Pinholing

- Plucking

- Pug Mill

- Pyrometric Cones

- Raku

- Rib

- Sgraffito

- Shelf Of Shame

- Slab Roller

- Slip

- Test Tile

- Knowledge

- Frequently Ignored Answers

- Photography

- Photographers

- Photo Links

- Raw File Converters

- Camera Simulators

- Color Vision Games

- Frequently Ignored Answers

- Resources

- Contact

Pyrometric Cones

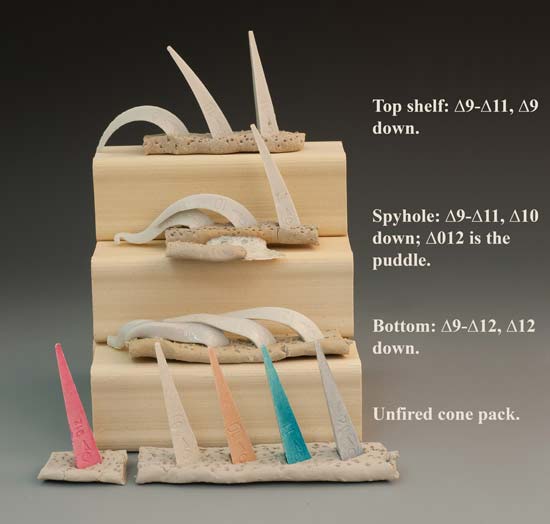

Pictured above: large standard cones and small cones.

Small triangular cones of ceramic material, designed to melt after absorbing specific amounts of heat. Used to determine how a kiln firing is progressing and when it should be ended. Cones are designated by numbers according to how much heat work it takes to melt them, and so these cones and their numbers form a scale used to measure the heat work that takes place in a kiln. Numbers on the cone scale are associated with the peak temperatures reached if the kiln temperature is raised at a certain rate.

Relying on pyrometer readings to fire a kiln to a temperature listed as the equivalent of a certain cone is not as reliable as using cones to measure the heat work. As kilns (especially fuel kilns) do not heat perfectly evenly, a lot can be learned about how a kiln fires by placing cones packs at various places in the kiln and, after the kiln has fired, seeing how the heat work varies from place to place.

Small cones are used in electric kilns. A single cone of the desired rating is wedged between the top and bottom fingers of a kilnsitter; when the kiln reaches temperature, the cone bends and the fingers close, causing the kiln to shut off.

Large cones are stuck base-down into small wads of clay so that they stand upright, leaning at a slight angle. As the heat work done by the kiln approaches the cone's rating, the cone begins to bend over, until the tip touches the cone's base level and the cone is said to be "down" and the rated heat work achieved. Large cones are grouped into "cone packs", strips of clay usually holding three or more cones: one "guide cone" rated a cone lower than the desired heat work to tell the kiln is getting close, one "target cone" rated to bend when the desired heat work has been achieved, and a "guard cone" rated a cone higher than the desired heat work to tell if/how much the kiln was over-fired. Cone packs are used not only to tell when a kiln has reached its peak temperature and needs to be shut off, but also to tell when to start or end reduction or oxidation atmospheres.

"Witness cones" - those you want to be able to see in order to control the firing, need to be visible from a spyhole, which can require a little juggling at times. Trying to see them through a flaming spyhole in a smoky kiln can be a challenge: make sure to wear welding goggles or similar, so the IR doesn't hard-boil your poor wee eyeballs over time, and don't get too close. If you hear a faint crackling and get a whiff of a nasty smell? - your hair is on fire: pat yourself on the head to put it out and give yourself a stupid medal.

Below is a picture of the cone packs from one very uneven cone 10 firing, along with an unfired cone pack.