- Ceramics

- Artist Pages

- Asian Ceramics & Tea

- Ceramics Artist Links

- Ceramics Links

- Ceramics Terms Glossary

- Agateware

- Banding Wheel

- Bat, Throwing Bat

- Bisqueware, Biscuit Ware

- Blistering

- Blow Up

- Boat Anchor

- Calipers

- Carbon Coring, Black Coring

- Carbon Trap

- Chuck, Chum

- Coil

- Colorants

- Crazing

- Downdraft Kiln

- EPK, Edgar Plastic Kaolin

- Electric Kiln

- Extrusion, Extruder

- Fettle, Fettling Knife

- Force Dry

- Greenware

- Kaolinite

- Kilnsitter

- Overglaze

- Pinholing

- Plucking

- Pug Mill

- Pyrometric Cones

- Raku

- Rib

- Sgraffito

- Shelf Of Shame

- Slab Roller

- Slip

- Test Tile

- Knowledge

- Frequently Ignored Answers

- Photography

- Photographers

- Photo Links

- Raw File Converters

- Camera Simulators

- Color Vision Games

- Frequently Ignored Answers

- Resources

- Contact

Carbon Trap

by Robert Andrilla

Carbon trapped under the surface of a glaze or clay body, giving it a black or gray appearance. Caused by putting the kiln in reduction as early as cone 013 and creating a smoky atmosphere before the clay or glaze surface seals up. Certain glazes, such as American carbon-trap shinos, make use of this to achieve a desired look.

If you want a carbon trap shino to fire black, you need to do more than just dip it in glaze and fire it: you need to let it dry for a least a day or two first. Soda ash (sodium carbonate - Na2CO3), the glaze component that traps carbon in the glaze, is soluble in water, and so when the pot is glazed the soda ash soaks into the pot rather than remaining on the surface. As the pot and glaze slowly dries, the evaporating water carries the soda ash back to the pot's surface, where it is deposited as a fine white powder (that is easily brushed off, if you are not careful).

Where you see the soda ash is where the carbon will be trapped and the pot will turn gray/black; if you can control how the pot dries and when the kiln is fired, you can influence how the glaze turns out. One simple way to create contrasting orange/pale areas in the glaze is to paint wax resist over the glaze coat: the water can't evaporate from under the wax, and so the water and soda ash escape around it.

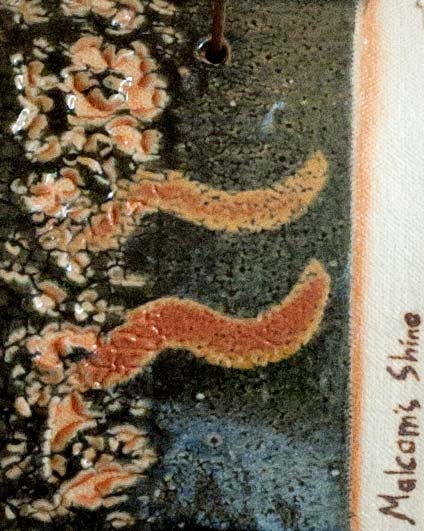

Below, a test tile with Malcom's shino; wax resist was painted over the glaze after it was just dry, then the tile was left to dry for three days before firing.

For more on shinos and carbon trap firing, read Ben Brierley's excellent article on the subject.